precast box culvert, precast concrete manufacturers, precast concrete drains

precast box culvert, precast concrete manufacturers, precast concrete drains

Box Culvert

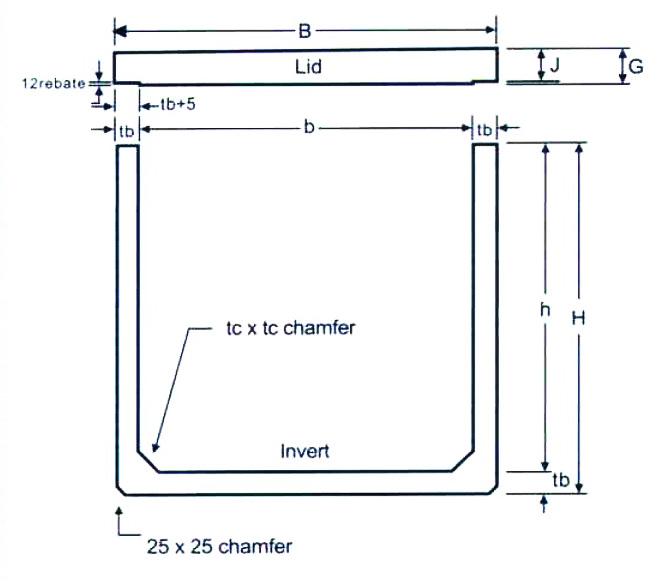

SMALL SIZE BOX CULVERT DIMENSIONS & PORPERTIES

| NORMAL SIZE (mm x mm) |

B (mm) |

bt (mm) |

bb (mm) |

h (mm) |

H (mm) |

C (mm) |

t (mm) |

tt (mm) |

tb (mm) |

G (mm) |

WEIGHT (tonnes) |

|

| Lid | Invert | |||||||||||

| 300 x 300 | 420 | 300 | 290 | 300 | 360 | 60 | 60 | 60 | 65 | 80 | 0.11 | 0.2 |

| 300 x 450 | 425 | 305 | 290 | 450 | 510 | 60 | 60 | 60 | 67 | 80 | 0.11 | 0.26 |

| 300 x 600 | 430 | 310 | 290 | 600 | 665 | 60 | 65 | 60 | 70 | 80 | 0.11 | 0.33 |

| 450 x 450 | 575 | 455 | 440 | 450 | 510 | 60 | 60 | 60 | 67 | 100 | 0.18 | 0.29 |

| 450 x 600 | 580 | 460 | 440 | 600 | 665 | 60 | 65 | 60 | 70 | 100 | 0.18 | 0.36 |

*Scroll to right to see more details.

STANDARD SIZE BOX CULVERT WITHOUT DRY WEATHER FLOW [BC]

STANDARD SIZE BOX CULVERT WITHOUT DRY WEATHER FLOW [BC]

| NORMAL SIZE | DIMENSION | WEIGHT (tonnes) |

|||||||

| b (mm) |

h (mm) |

B (mm) |

H (mm) |

tb (mm) |

tc (mm) |

G (mm) |

J (mm) |

Lid | Invert |

| 600 | 300 450 600 |

740 740 740 |

370 520 670 |

70 70 70 |

70 70 70 |

140 140 140 |

128 128 128 |

0.26 0.26 0.26 |

0.24 0.30 0.35 |

| 750 | 450 600 750 |

910 910 910 |

530 680 830 |

80 80 80 |

80 80 80 |

140 140 140 |

128 128 128 |

0.32 0.32 0.32 |

0.37 0.43 0.49 |

| 900 | 450 600 750 900 |

1060 1060 1060 1060 |

530 680 830 980 |

80 80 80 80 |

80 80 80 80 |

140 140 140 140 |

128 128 128 128 |

0.37 0.37 0.37 0.37 |

0.40 0.46 0.52 0.58 |

| 1200 | 600 750 900 1050 1200 |

1390 1390 1390 1390 1390 |

695 845 995 1145 1295 |

95 95 95 95 95 |

95 95 95 95 95 |

150 150 150 150 150 |

138 138 138 138 138 |

0.51 0.51 0.51 0.51 0.51 |

0.61 0.68 0.75 0.82 0.89 |

| 1500 | 750 900 1050 1200 1350 1500 |

1700 1700 1700 1700 1700 1700 |

850 1000 1150 1300 1450 1600 |

100 100 100 100 100 100 |

100 100 100 100 100 100 |

175 175 175 175 175 175 |

163 163 163 163 163 163 |

0.73 0.73 0.73 0.73 0.73 0.73 |

0.81 0.88 0.96 1.03 1.10 1.18 |

| 1800 | 900 1050 1200 1350 1500 1650 1800 |

2030 2030 2030 2030 2030 2030 2030 |

1050 1165 1315 1465 1615 1765 1915 |

115 115 115 115 115 115 115 |

115 115 115 115 115 115 115 |

175 175 175 175 175 175 175 |

163 163 163 163 163 163 163 |

0.87 0.87 0.87 0.87 0.87 0.87 0.87 |

1.11 1.20 1.28 1.37 1.45 1.54 1.62 |

*Scroll to right to see more details.

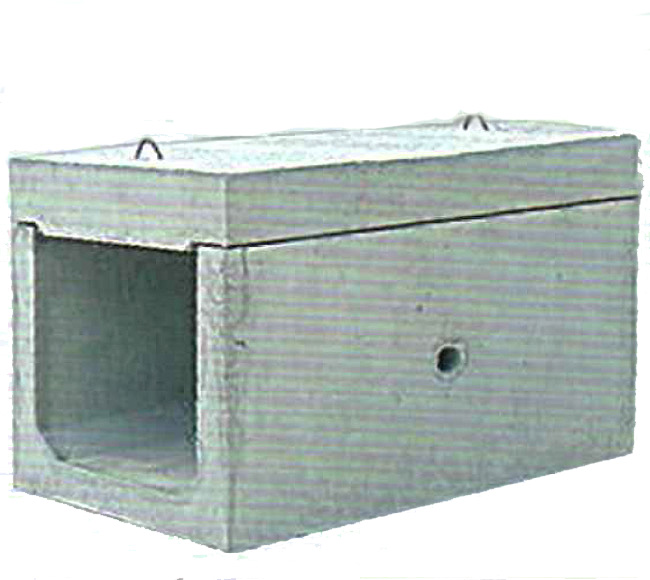

FEATURE OF UCP PRECAST R.C BOX CULVERT

MUCPTM Box Culverts are available in both Standard Size (for nominal width between 600mm and 1800mm) and Super Size (for nominal width between 2100mm and 3600mm) in length of 1 meter as shown in Table 1,2 and 3. MUCPTM Box Culverts are available in both WITH and WITHOUT Dry Weather Flow [DWF) channels.

DESIGN CONSIDERATIONS

1. Design loading requirements for MUCPTM Box Culverts are in accordance with:

a) BS 5400: Part 2: 1978 modified by [b]

b) Department Standard BD31/01 Buried Concrete Box Type Structure issued by Departmental of Transport [UK]-Highway and Traffic.

c) JKR LTAL [Long Term Axle Load] and SV [Special Vehicle] requirements.

2. The design of Precast Reinforced Concrete Box Culverts is in accordance with BS 5400: Part 4: 1984.

3. MUCPTM Box Culverts are made from high strength concrete with a 28days characteristic strength of 40 N/mm2. Our products are produced by good quality Portland Pulverized-Fuel Ash Cement [PFA), which can perform much better in workability, durability and long term strength.

4. Concrete cover to reinforcement for:

- Standard Size Box Culverts = 25mm

- Super Size Box Culverts =30mm

5. Coefficient of the earth lateral pressure at rest = 0.6 and bulk density of soil =19KN/m3

6. MUCPTM Standard Size Box Culverts also comply with proof load test of 112.5KN over and area of 320mm x 320mm placed at any position on the Culverts Lid in Accordance with MS 1293: Part 1: 1992.

7. Hydrostatic pressure is eliminated by provision of 50mm diameter weep holes placed along the centerline of the invert wall.

8. The prepared bedding or piled foundation by others shall be adequate which would not cause any reverse effect to the culvert.

9. The backfill material adjacent to wall should be granular type of soil.

10. Standard supply of MUCPTM Standard Size Box Culverts [Not Exceeding 1800mm width and height] and Super Size Box Culverts [Exceeding 1800mm width and height] are designed to cater for backfill superimposed dead load NOT EXCEEDING 2.0 meter plus 45 units HB vehicle primary live loads.

11. For Box Culverts (Standard Size and Super Size] to cater for backfill MORE than 2.0 meter or NO backfill [direct impact], kindly refer to our Technical or Marketing Department.

12. For other loading conditions or sizes not shown in the tables here, please contact out Technical or Marketing Department for a special design.

STACKING

All inverts should be stacked uniformly on leveled ground.Lids should be supported with timber bearers at both end.

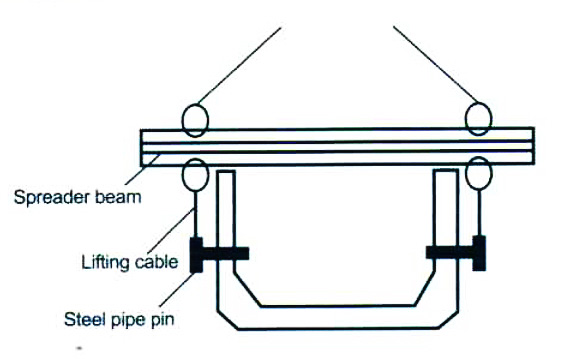

HANDING

Lifting holes [weep holes] are provided at the box culverts wall and lifting hooks are provided at both ends of lid for handing. It is recommended that a spreader beam to be used when slinging the inverts to avoid cracking at the wall base joint.

JOINTING

MUCPTM Box Culverts are supplied with plain butt joints. Cement mortar is normally used to fill the gap between box culverts.

LAYING PROCEDURE

MUCPTM Box Culverts should be laid on the prepared bedding [preferable) compacted sand bedding]. However, in bad ground, it may be necessary to excavate deeper or provide with piled foundation [by others] and place a layer of hardcore before placing the sand bedding in accordance to the engineer's [or s.o] specifications and details. Backfilling around culverts units should be done after the lid of the culverts has been installed and it should be carried out in even layers on both sides simultaneously.

For direct impact condition, the backfilling work has to be carried out together with proper compaction method to prevent ground settlement. Different level between the lid and ground will cause the horizontal force during passing by vehicle, which will damage the invert of the culvert

Accreditation & Certification